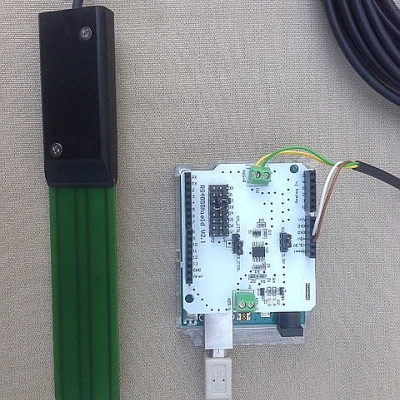

SMT100 with 4 - 20 mA interface

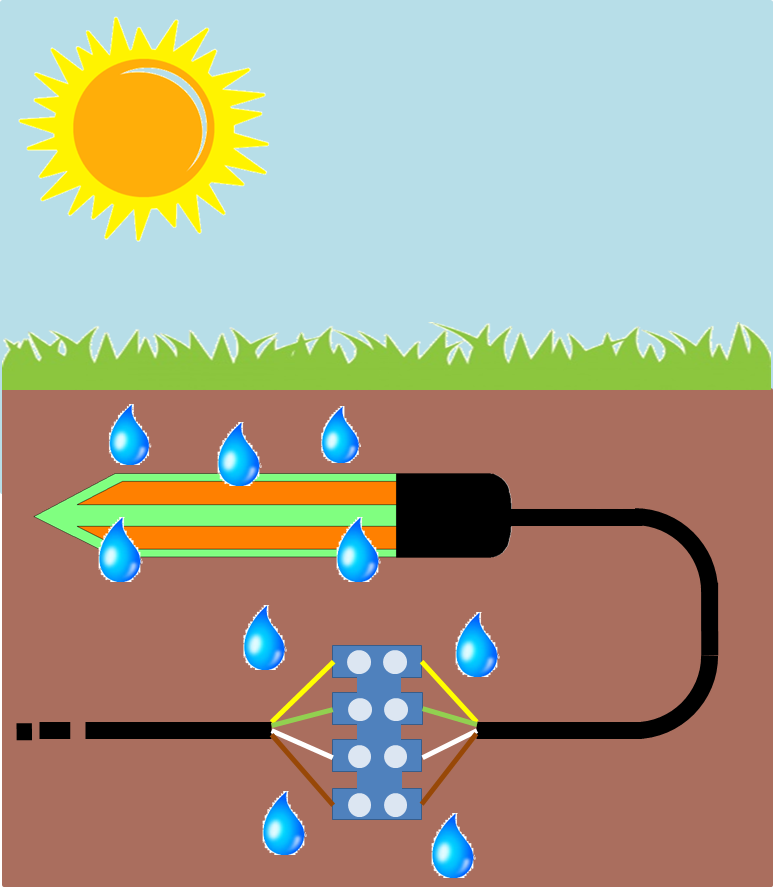

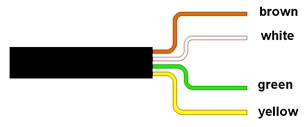

The 4 - 20 mA interface or current loop is still very popular in process control automation. There are a couple of advantages:

- Only 2 wires are required (if sensor is low power and requires less than 4 mA current)

- Voltage drop along the interconnection wires does not degrade accuracy, so extremely long cables are possible

- Broken cable can be identified (no current)

- High noise immunity (because of relatively high currents)

The disadvantage is:

- Power consumption high and relatively high supply voltages required (typically 12 V to 24 V DC)

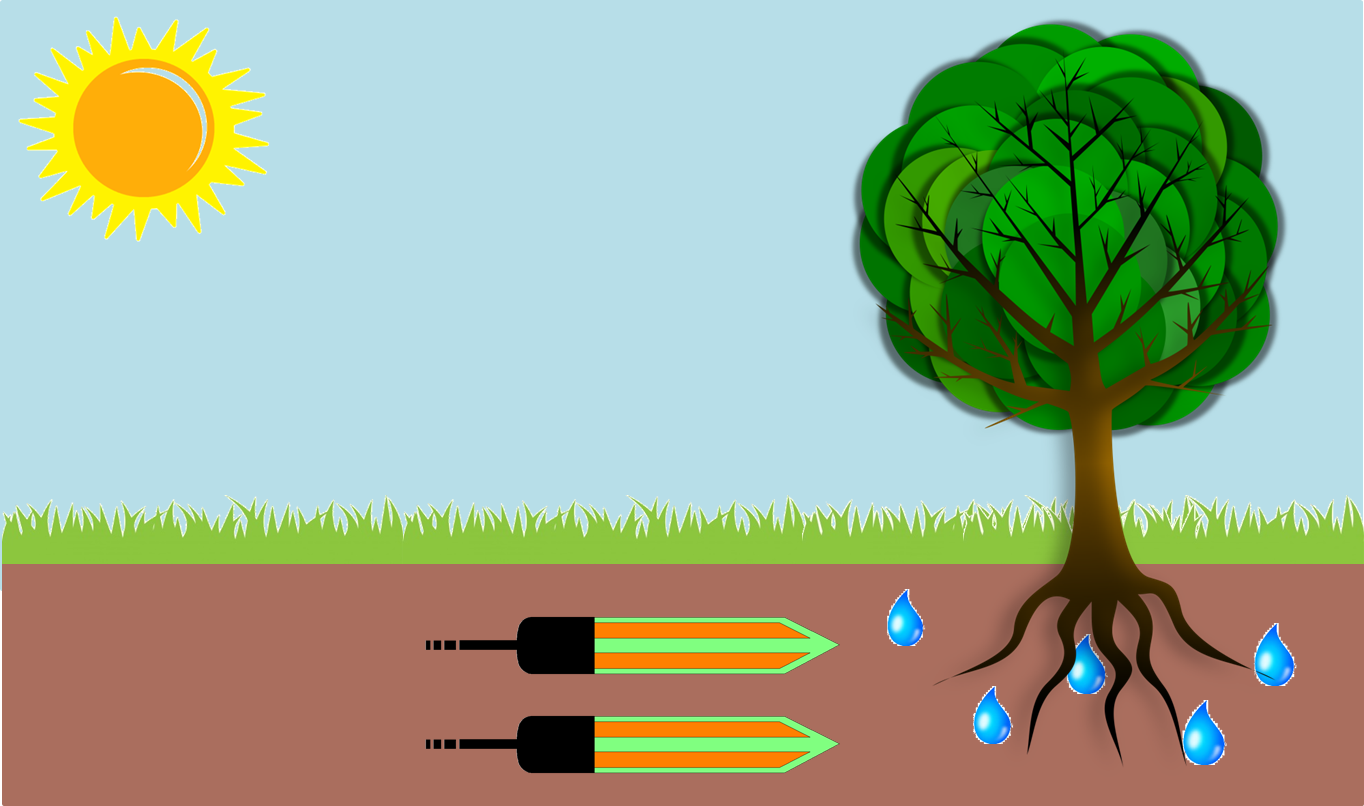

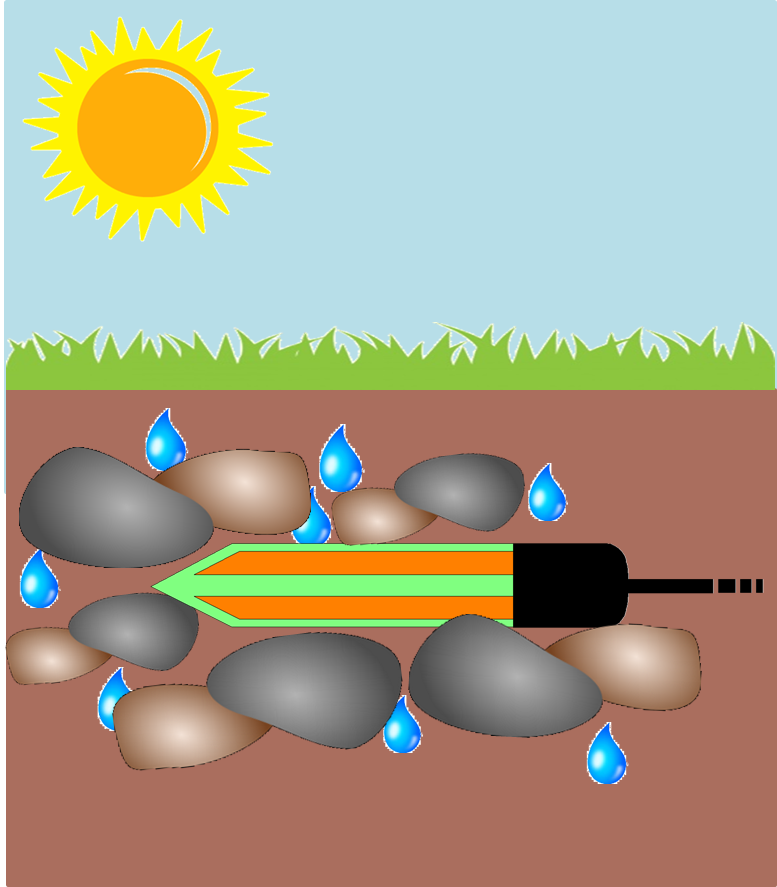

Generally I prefer digital interfaces like RS-485, but easy to use 4 - 20 mA sensor are ideally suited for my farmsite so that even untrained personnel can install or replace sensors without configuration hassle.

The choice of 4 - 20 mA sensors for soil moisture measurement is quite limited. Besides other disadvantages, Chinese sensors like Sonbus SM2801 or those from Rika are not real 2 wire sensors. A converter module by Vegetronix for voltage output sensors does not help as well since it requires an external power supply, so no real 2 wire solution as well. Even higher quality sensors like Gropoint are not a 2 wire solution. In the end I only found one real 2 wire solution which is from Decagon (now Metergroup) with their MAS-1 (and probably some OEM variants which look exactly the same). Unfortunately the manual of the MAS-1 contained an unpleasant surprise. The accuracy in volumetric water content is 6% which is mediocre but acceptable. What is more worrying is that the sensor air shall transmit approximately between 3.4 mA and 4.7 mA. I believe this is quite a very large tolerance since I hoped that at least in air it should be quite close to 4 mA. Fortunately a 4 - 20 mA variant of the SMT100 recently came on the market. I already own a couple of SMT100 with RS-485 interface for my garden irrigation system which are working fine, so I decided to give it a try with a SMT100 4 - 20 mA, which arrived these days. My first test was current measurement in air and the SMT100 was 4.03 mA, so right on spot. Even with 100 m cable length no degradation could be observed. So this is a good start for my upcoming farmsite project I hopefully can report on in the future.