Installation of a capacitive soil moisture probe is simple. However, there are a few important points which should be considered in order to achieve a good measurement result.

So here is some field work in my garden.

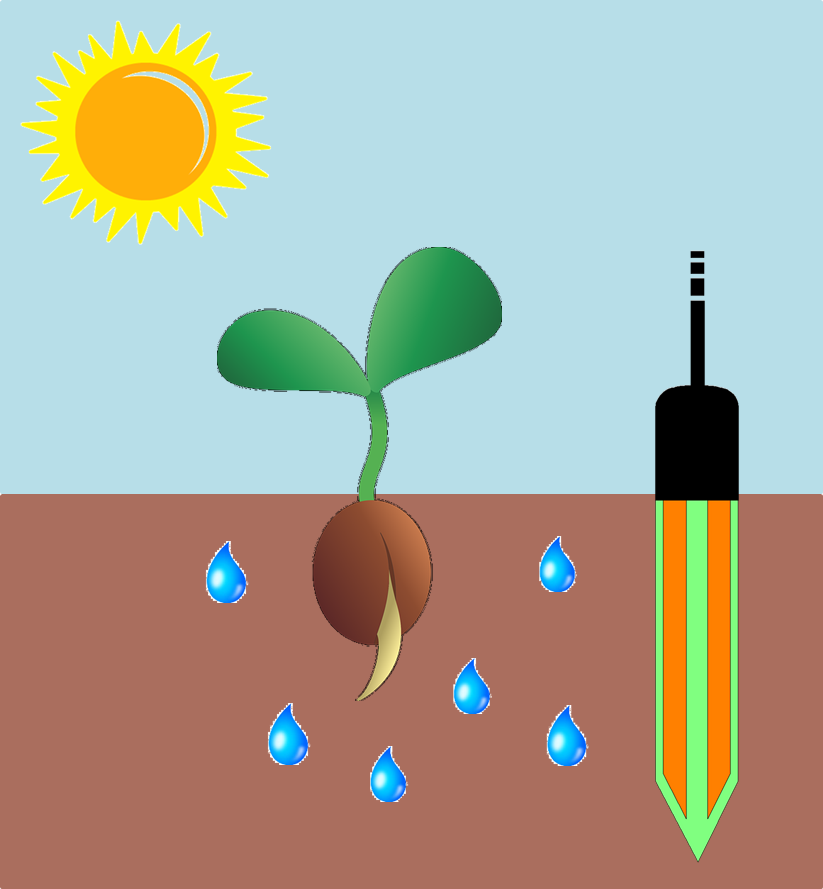

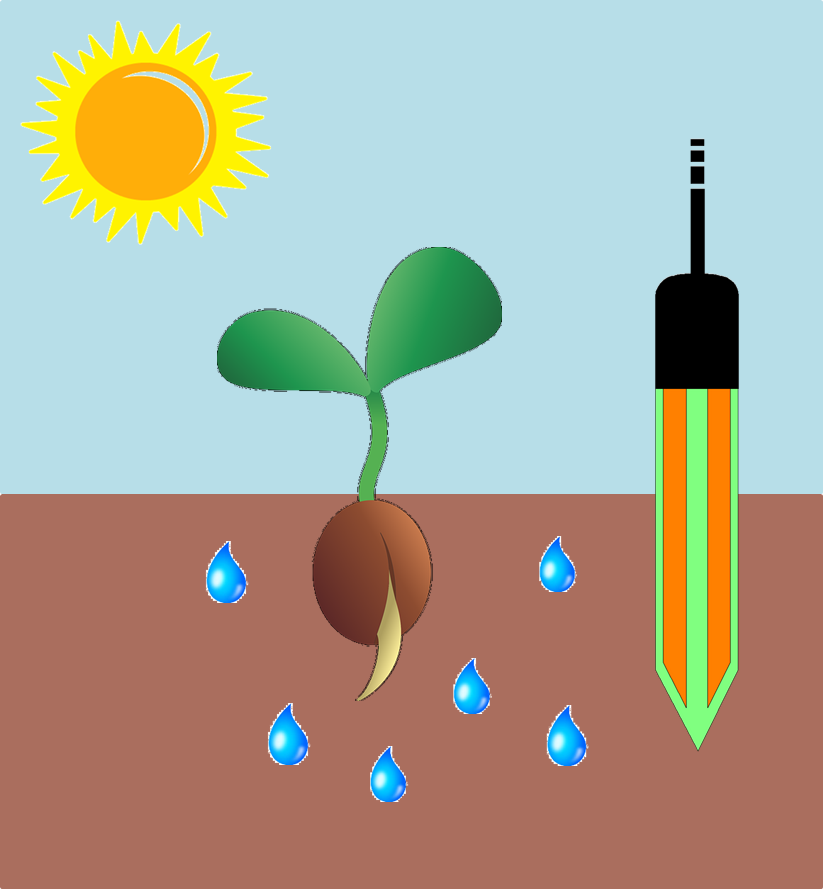

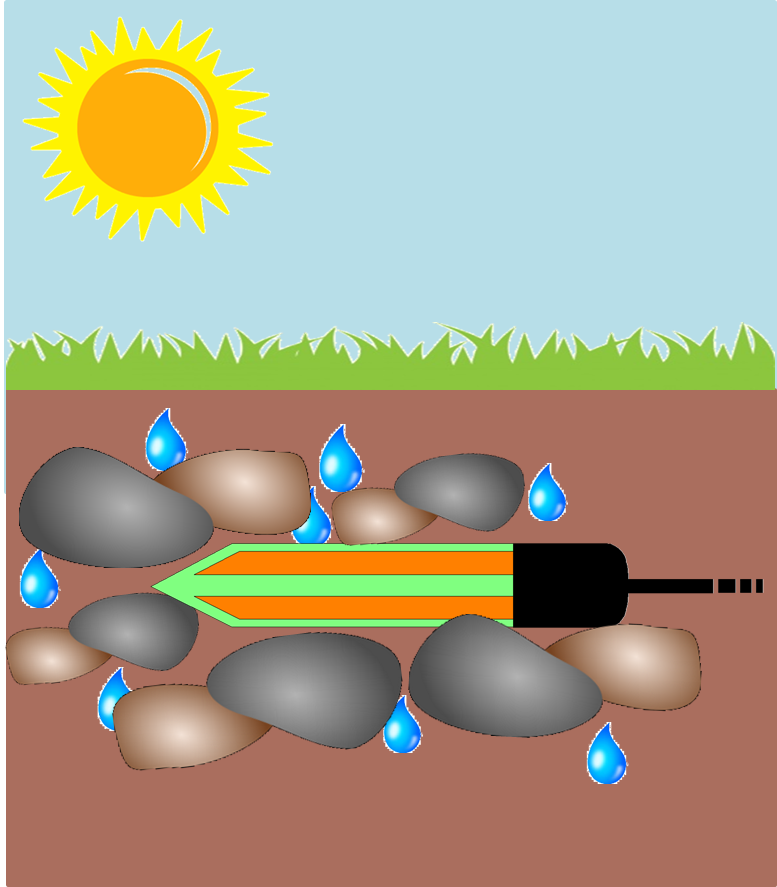

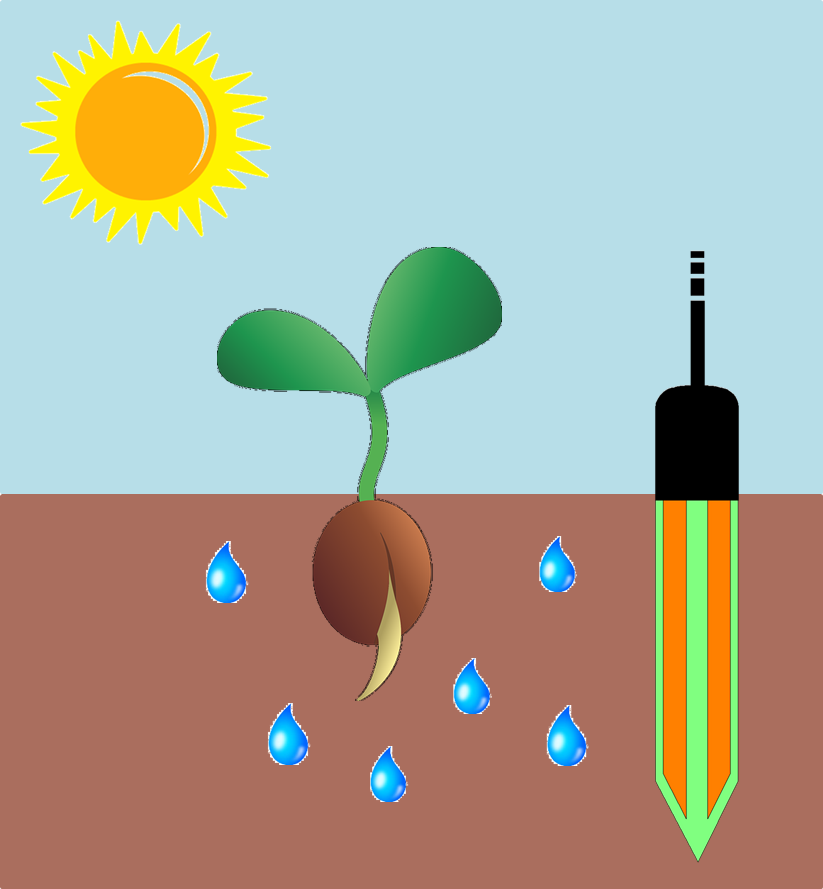

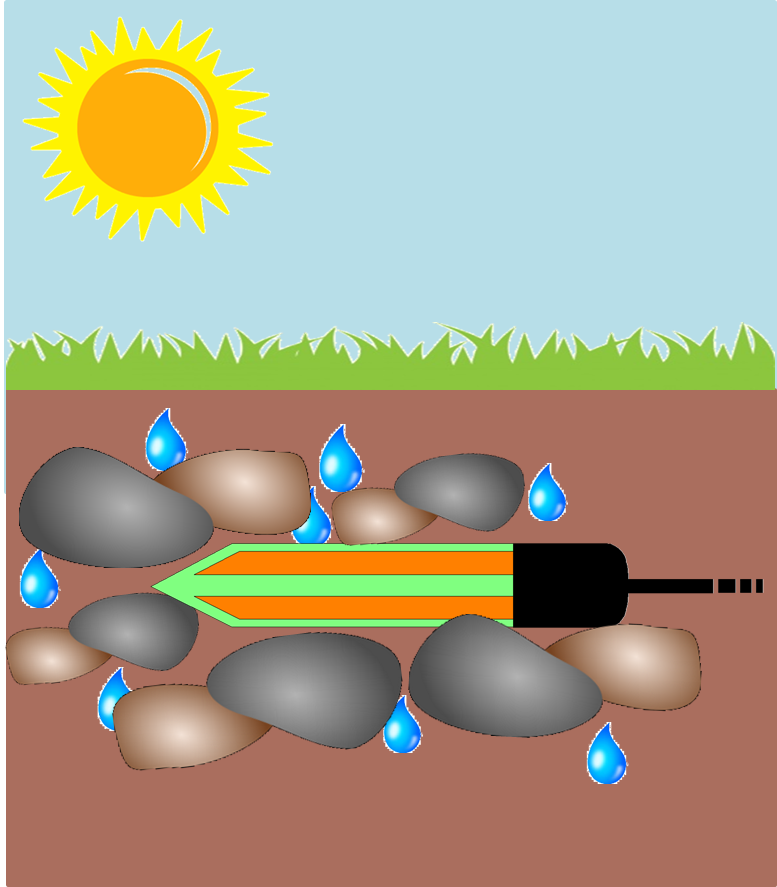

The figure below shows the correct installation of the SMT50 soil moisture sensor. It is mandatory to fully burry the probe including the black housing. A very good contact to the surrounding soil with no air gaps is very important because air gaps will lead to wrong soil moisture measurements. The density of the surrounding soil will influence the measurement signal. Make sure, the soil is properly compressed.

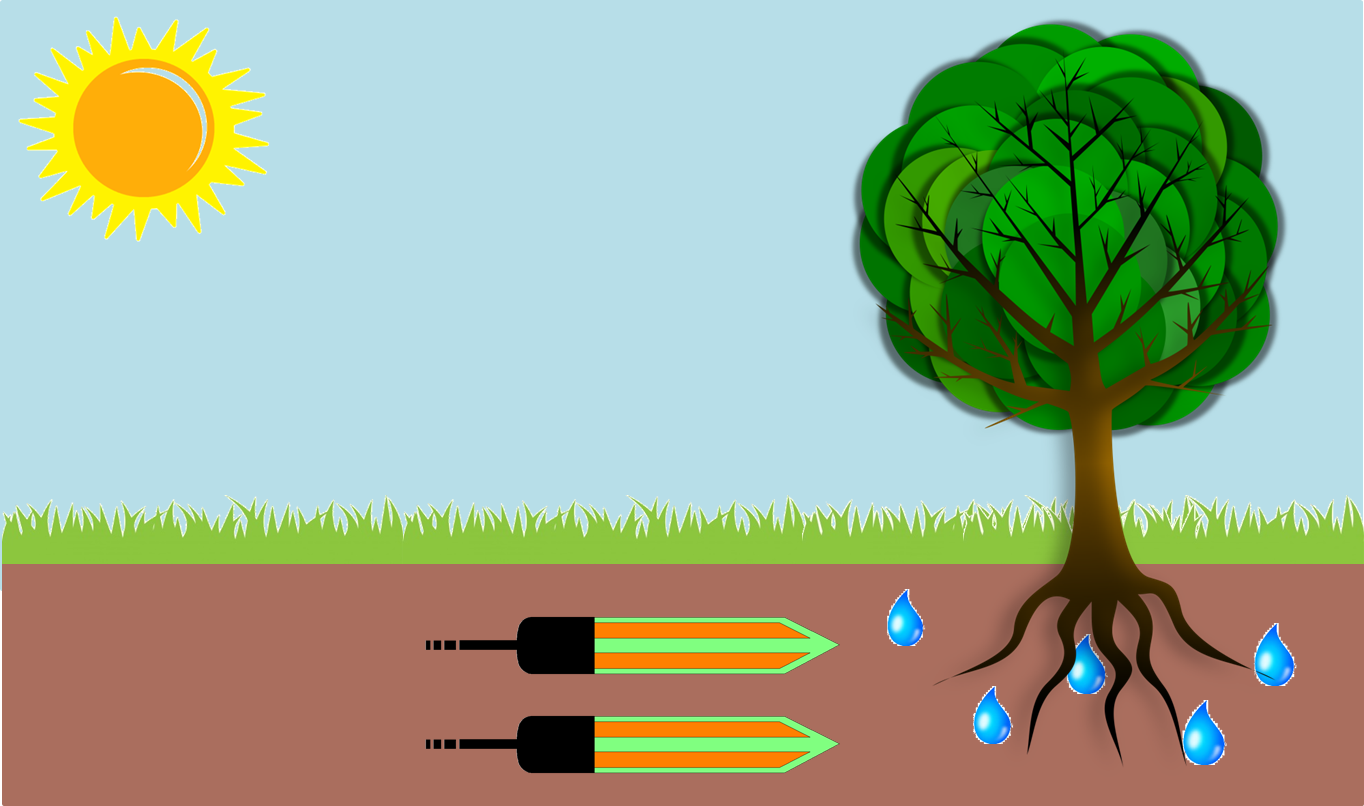

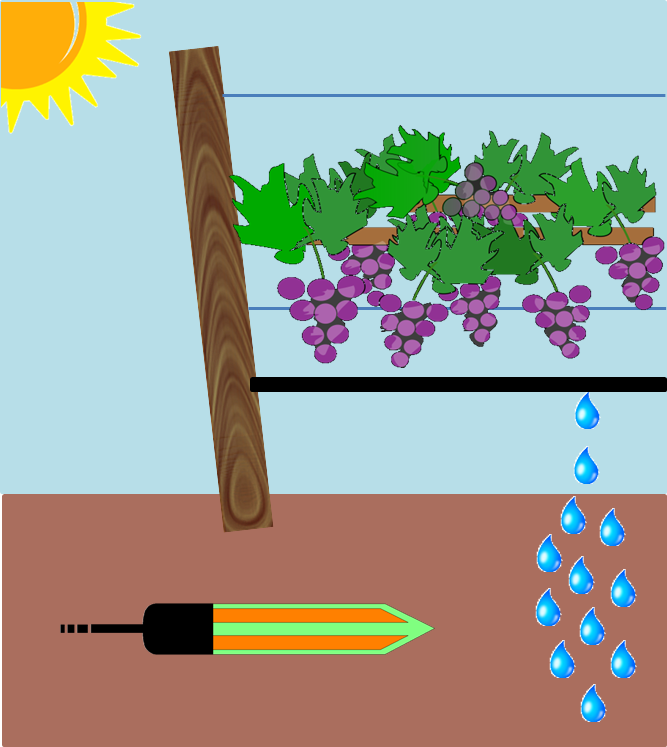

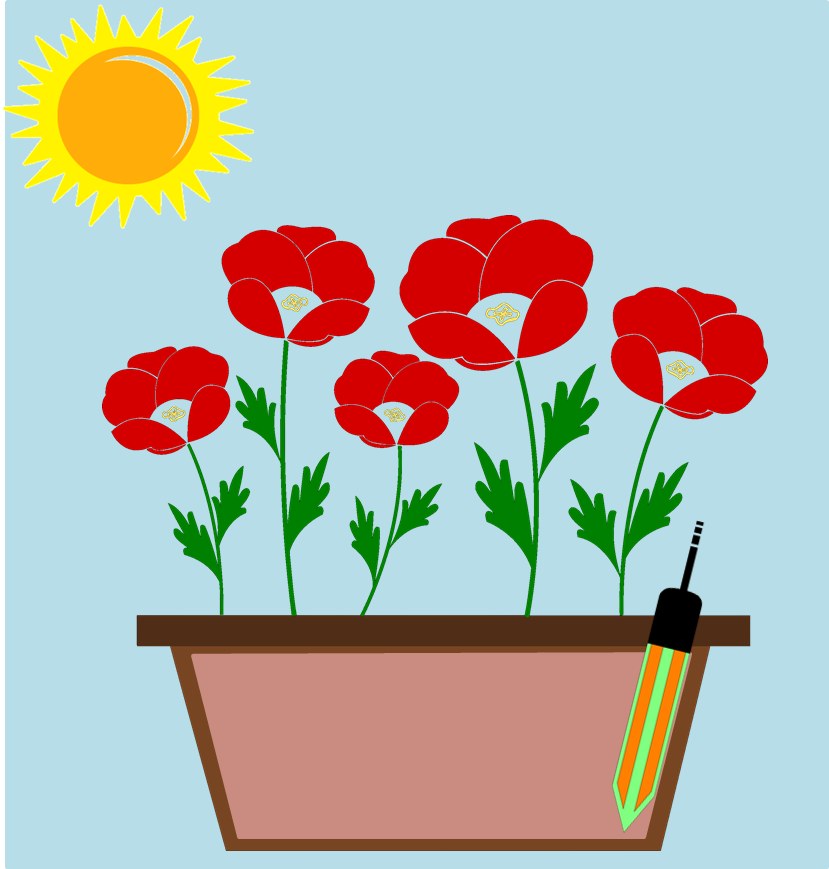

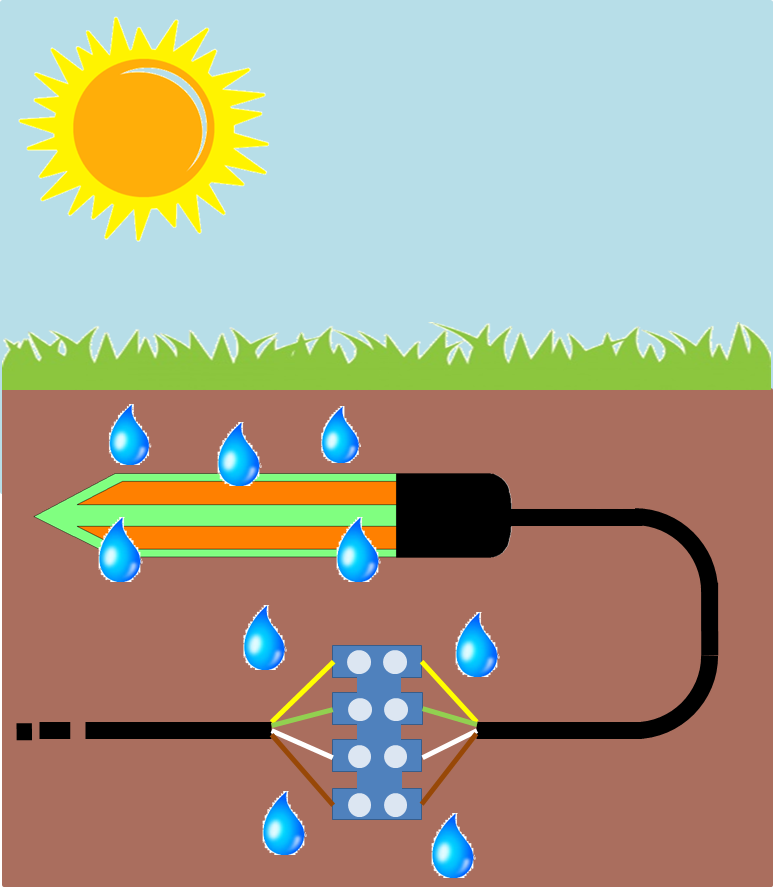

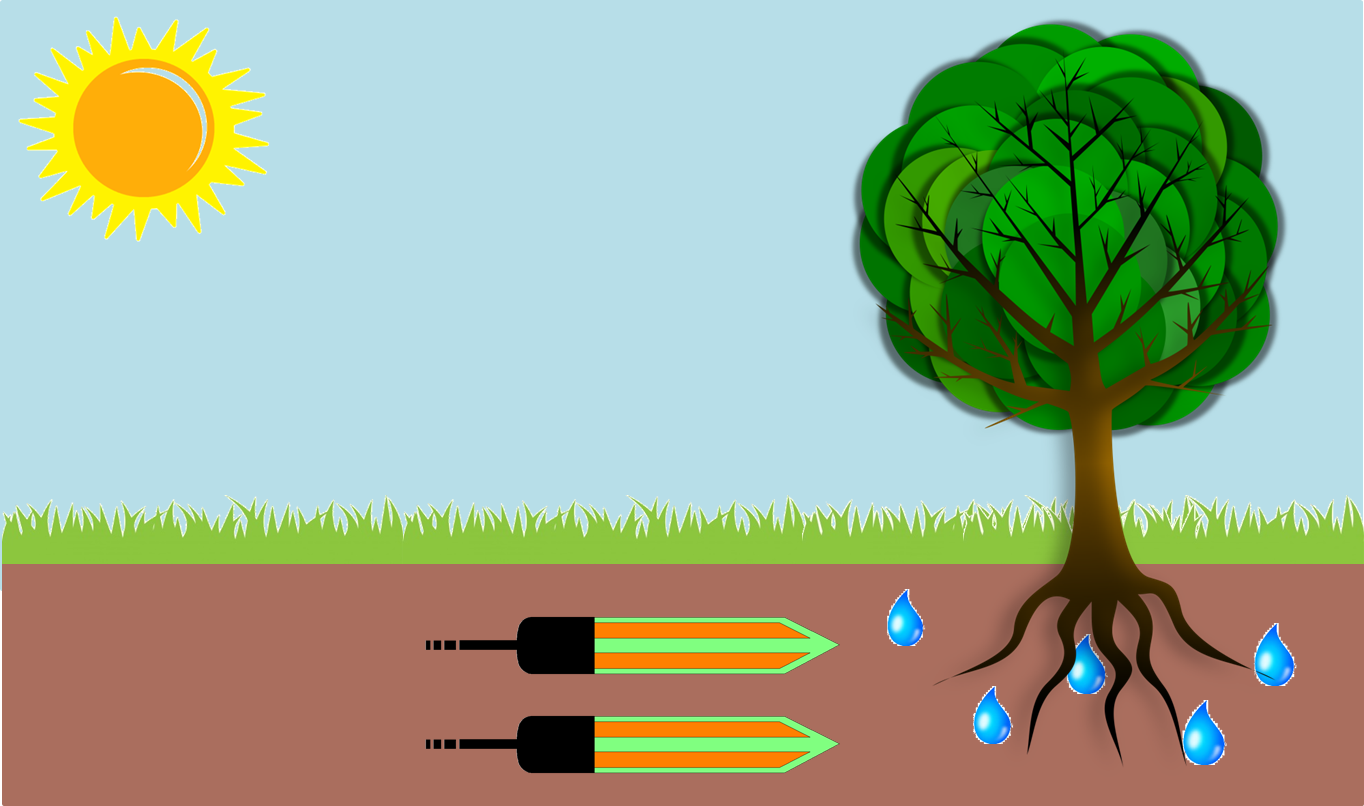

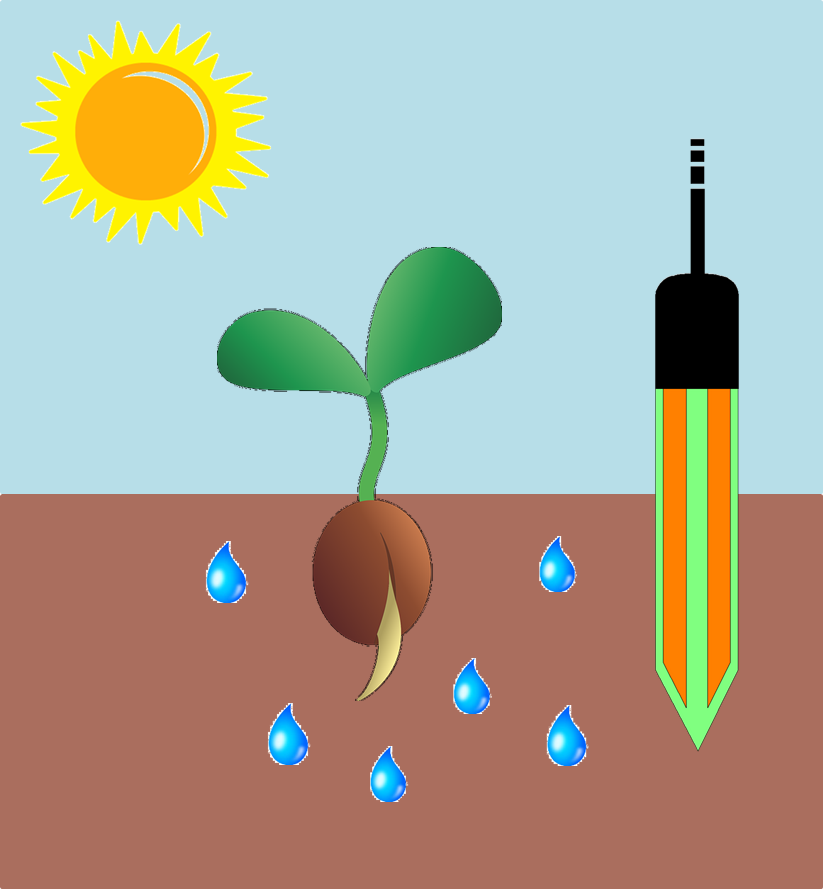

For irrigation purpose the SMT50 should be installed close to the roots of the plants. The ideal orientation of the sensor is a horizontal position. It is important to turn the sensor in an uprigth position so that no water can be accumulated on the surface of the green measurement area.

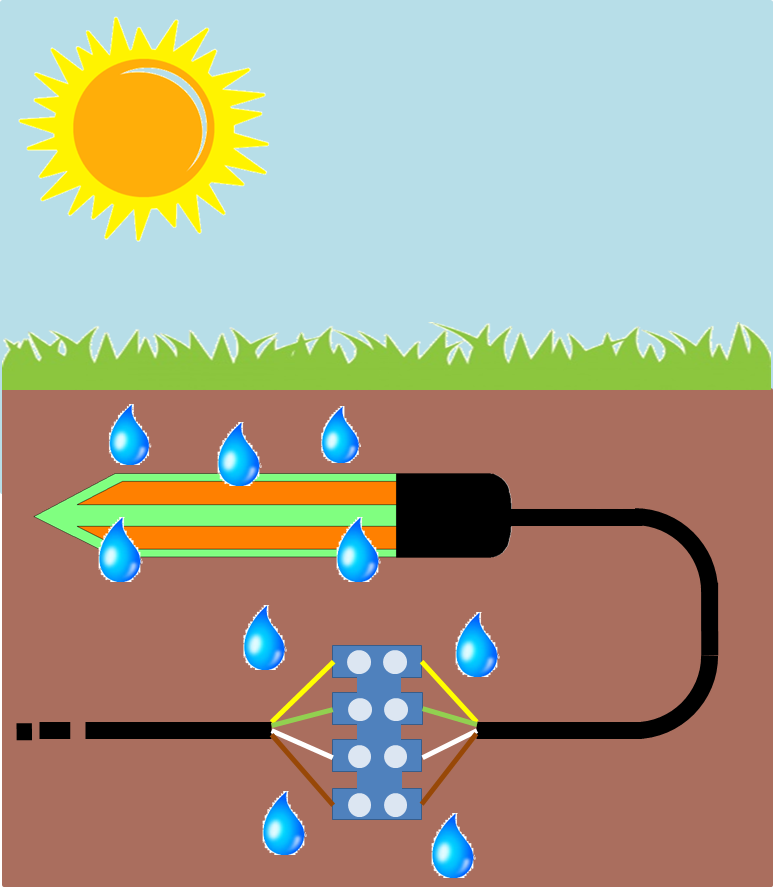

Sometimes it can be useful to embed two or more sensors in different depths. Then it is possible to see the penetration of the waterfront during the irrigation process. Based on this data the irrigation can be optimized.

Do not use a hammer for installation of the SMT50. If the soil is very compressed, it is recommended to use a punch or to soften up the soil by adding water.

The cable of the SMT50 is very robust and can directly be burried inside any type of soil. However, sometimes it can make sense to protect the cable against animal bites by using an additional ductwork.

Typical installation errors are shown below.

Temperature sensor is not burried in the soil -> Wrong temperature measurement

Measurement electrodes not fully burried -> Wrong moisture measurement

Large distance between sensor and dripping lines -> Sensor reacts to late / no reaction

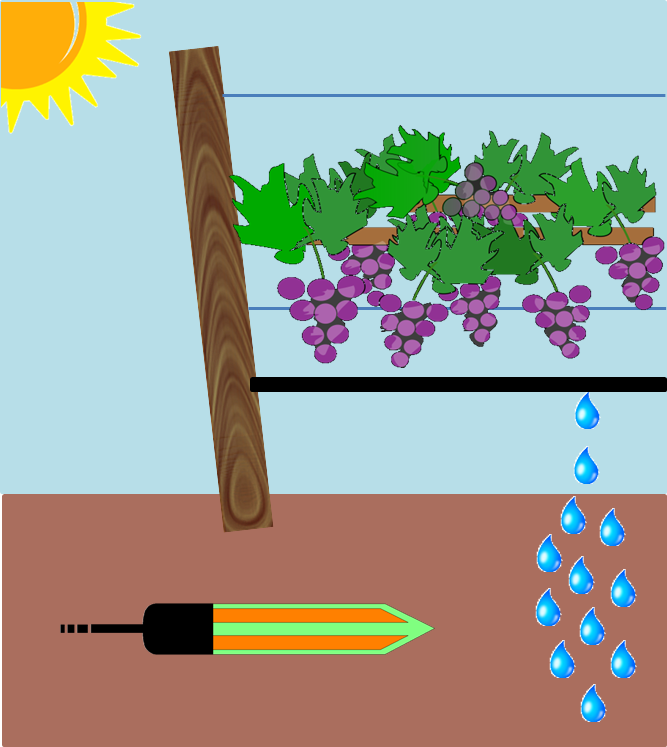

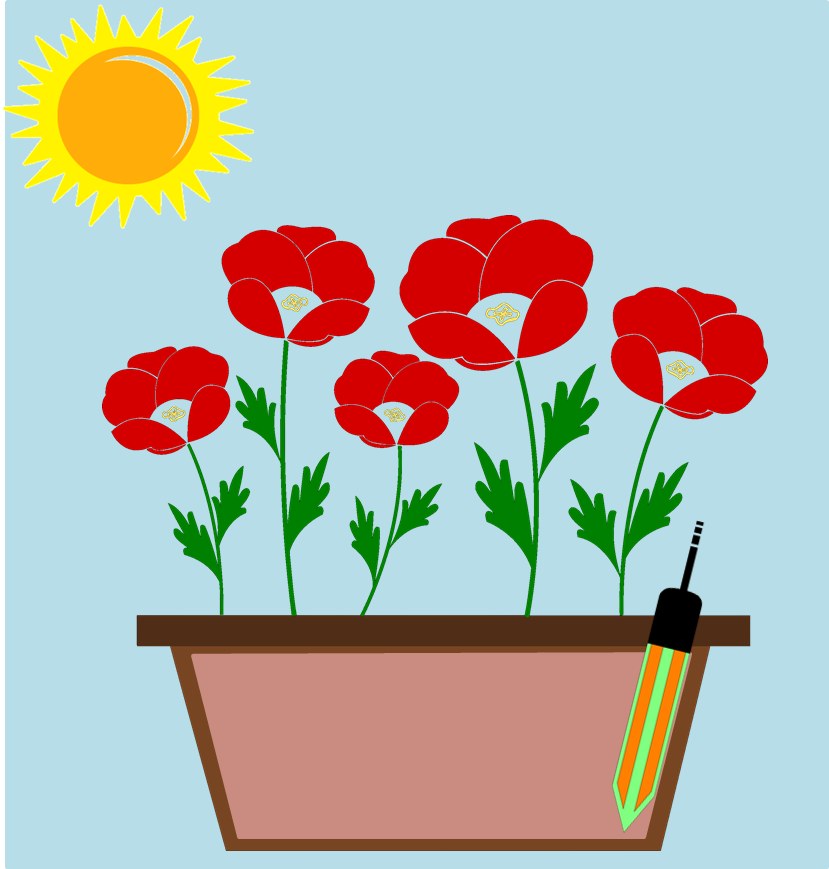

Sensor is positioned to close to the wall of a pot -> Wrong moisture measurement

Sensor is inside granular material with air gaps -> Wrong moisture measurement

Cable connections inside the (wet) soil -> Wrong output signal of the sensor